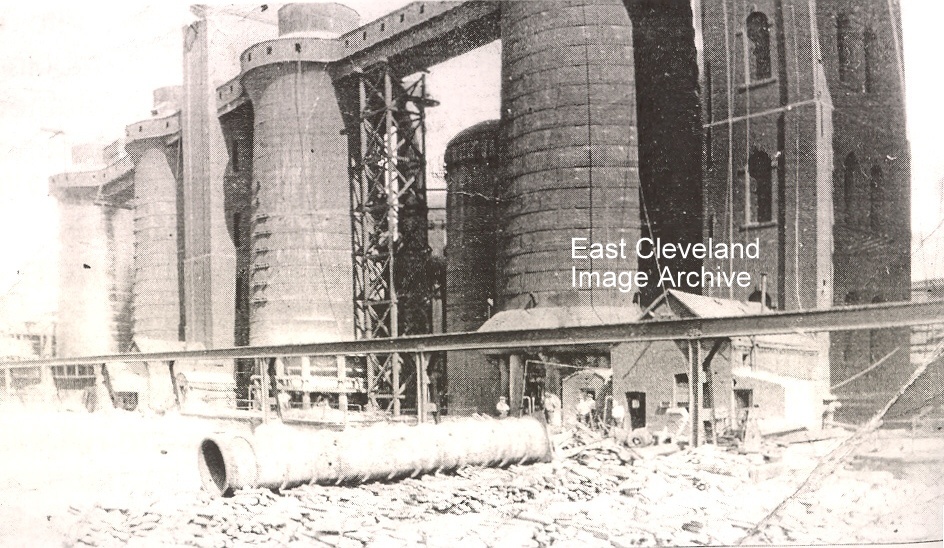

Not the shot of the blast furnaces that we usually see, but this shows more of the heaps of pig iron awaiting disposal; not sure what the large pipe section is though!

|

|

||

|

Not the shot of the blast furnaces that we usually see, but this shows more of the heaps of pig iron awaiting disposal; not sure what the large pipe section is though!

A modern view of a no. 5 casting; Bob Proctor tells us: ”If you ever wanted to view the inside of the furnace then you would use the eye piece, this is at the bottom of the silver goose-necks and looks like a protrusion. You would firstly make sure there was no leaking hot blast (500C) by moving your hand over the toughened glass eye-piece and then you could see through the blow pipe and tuyere into the heart of the furnace where the droplets of slag/iron cascaded down through the incandescent coke.” All working furnace-side wore blue glasses, otherwise their eyes would feel the pain! If possible using a sweat-rag, not their hand – 500C is not good for the skin! – but well-worth taking the precautions, it is a beautiful sight. The glass eye-piece (mica initially, then toughened quartz glass is called a pee-pee. Thanks to Bob Proctor for the comment.

Here’s a slag pot being filled after the iron has been run off, does this brings back many memories?

This is one of the older furnaces at Skinningrove with the crew barring out the tap hole; possibly ”Slaggers and Pig Bed Crew” in Skinningrove works. This must be quite an early photograph as none of the men are wearing a safety helmet. Middle man front row has his feet in ”Sow” channel for the molten iron.

This shows the steel-work being erected that will eventually contain the structure of No. 5 Blast Furnace. In the left hand image, the shape at the bottom right is the hearth structure. This feature was the hardest part of the furnace to remove after it was toppled, being constructed of solid carbon blocks.

This image (pre-1950) shows the left-hand man strapping on his clogs – shaped wooden soles to protect his rocker boots from the heat – before going in to do some hot work on the casting floor.

An image of a stack of pigs being stock-piled. The bar in the labourer’s hand is to break the pigs off the sow.

When the furnace has cast, the pigs are attached to the sow and the crew have to go around and break them off and heap them together in slings to be stock-piled.

Well…not quite. The tip labourer is spragging the wheel of the slag Bogie prior to tipping the slag over Cattersty Cliffs.They were tipped by using a chain and winch system through the hook on the side of the pots (on the other side of ladle). You can just see the chain hanging below the pot, to the left of the labourer. The Loco is one of the Low height types used on the Blast Furnaces. It certainly cast a lovely glow over the scene at night! Image courtesy of Dave McGill (a glass plate negative).

A pig bed with the gate irons in place ready to divert the flow of metal to fill the pigs. |

||

Recent Comments