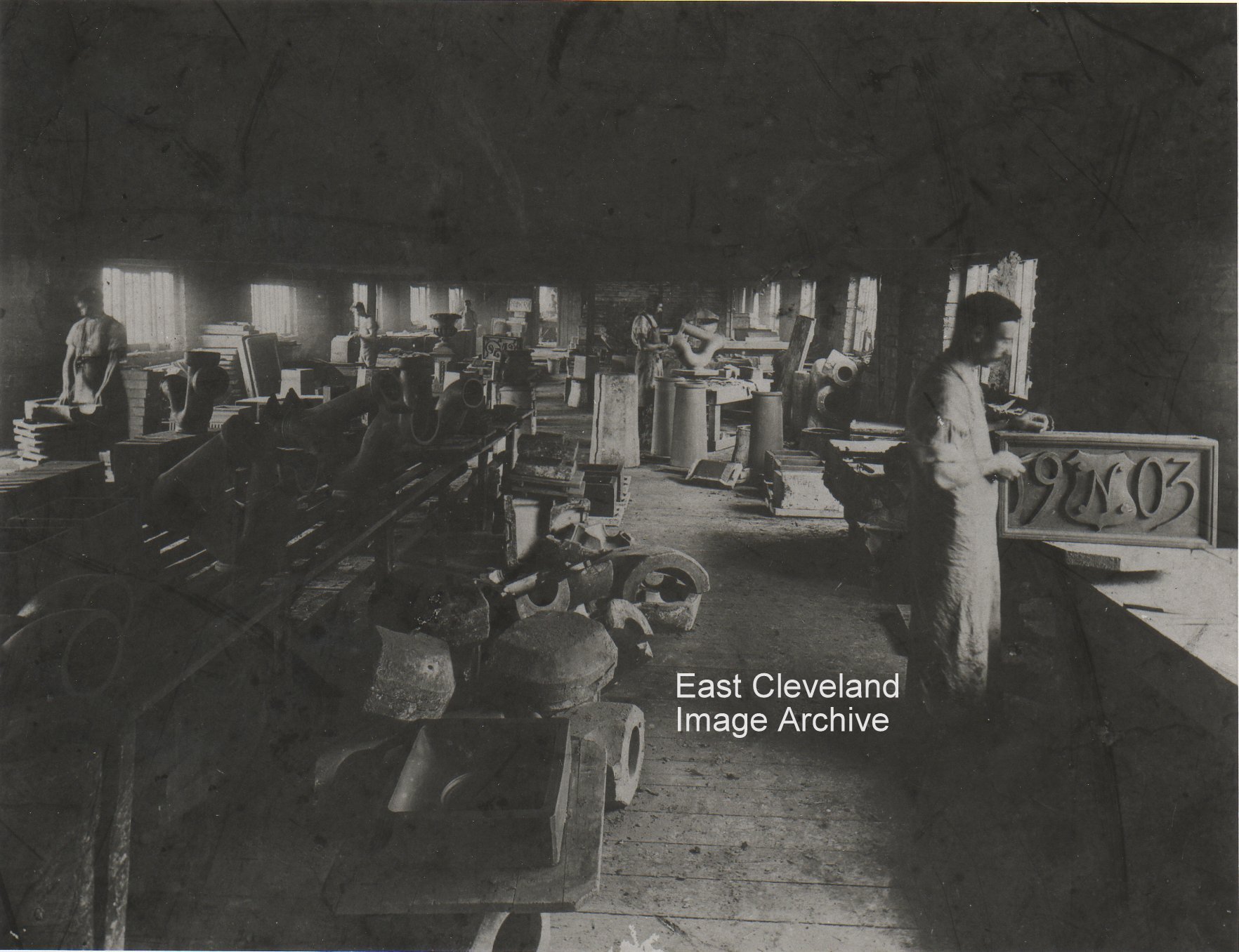

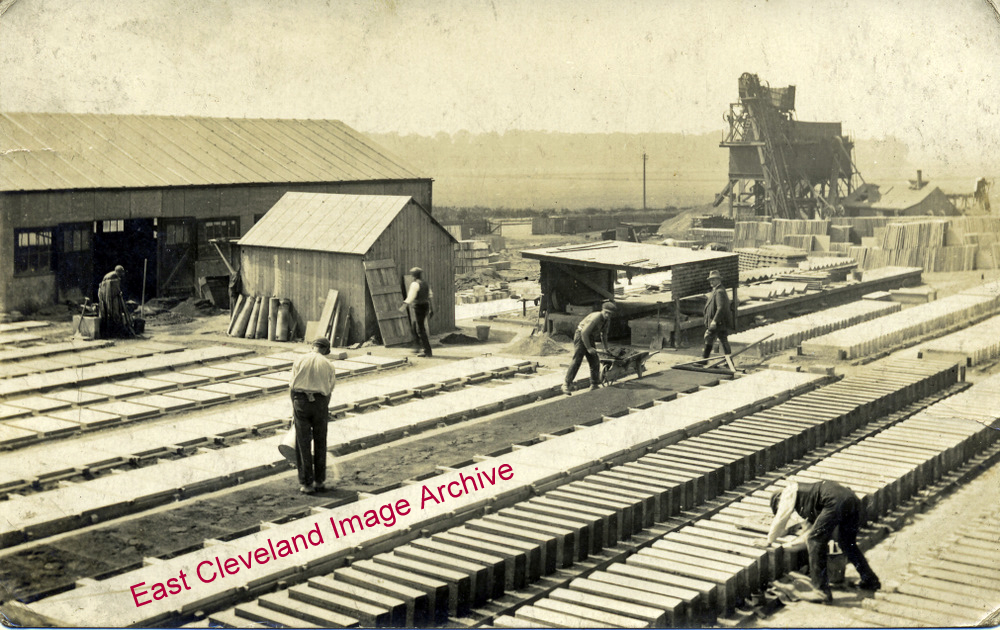

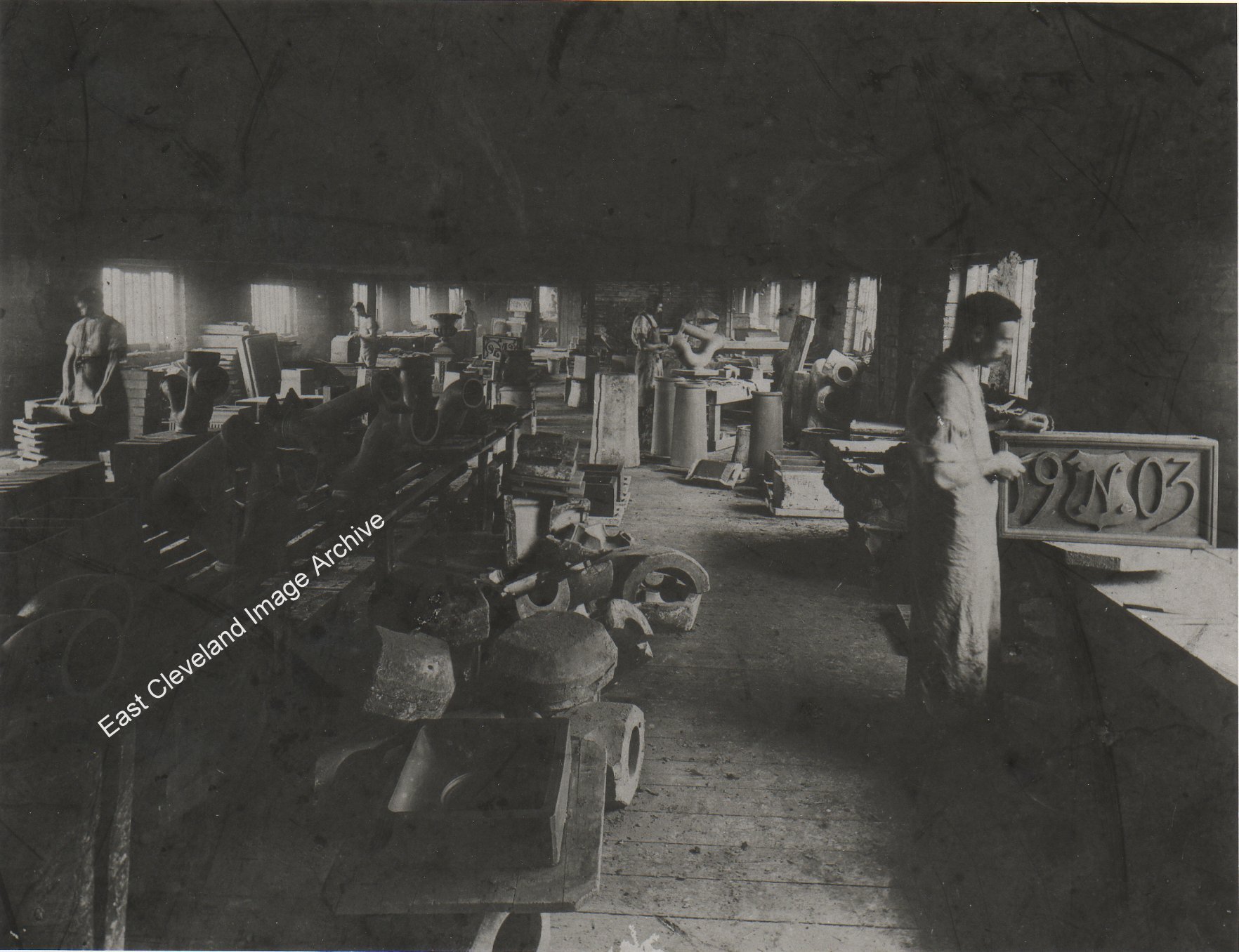

Previously shown on site as: ‘Ceramic Workshop’ we are now aware that it could not be the Loftus brickworks (where bricks were made from about 1830 to 1870s’) it is believed to be the workshops of the brick works at Commondale. In 1861, a Stokesley printer called John Pratt who owned land around the Commondale area did just that and set up his Cleveland Fire and Brick Company. The short-lived Commondale Pottery was set up by John Crossley, a retailer of building products from Stockton-on-Tees, on the site of a former brickworks which Crossley had acquired in 1872. The manufacture of art and domestic pottery was begun in April 1880, as an addition to the manufacture of bricks, tiles and pipes. The Commondale Pottery produced a wide range of domestic wares in both red and buff terracotta, some with elaborate painted and glazed decoration. After a short cessation in production and trading. The Commondale Brick & Pipe Works traded again from the late 1880s or early 1890s until 1947, when it closed. The brickworks site is now occupied by a Cleveland Scout campsite. Peter Appleton queries: “Anyone got any thoughts on where the “1903 N” special was destined to go? There’ll be a story lurking there, if it can be teased out.” Joan Smith asks: “My great grandad worked in a pottery round Middlesbrough, Stockton on tees , area in the late 1800s. He used to travel to Belgium, with his family, on more than one occasion. I am wondering what his job would have been. More importantly which pottery he would have worked for. His name was Christopher Dunning.” Peter Connor advises: “The 1903 stone that the man in the picture is working on is on the end of Ness Terrace in Commondale.”

Image courtesy of the Pem Holliday Collection, thanks to Peter Appleton, Joan Smith and Peter Connor for the updates.

Recent Comments