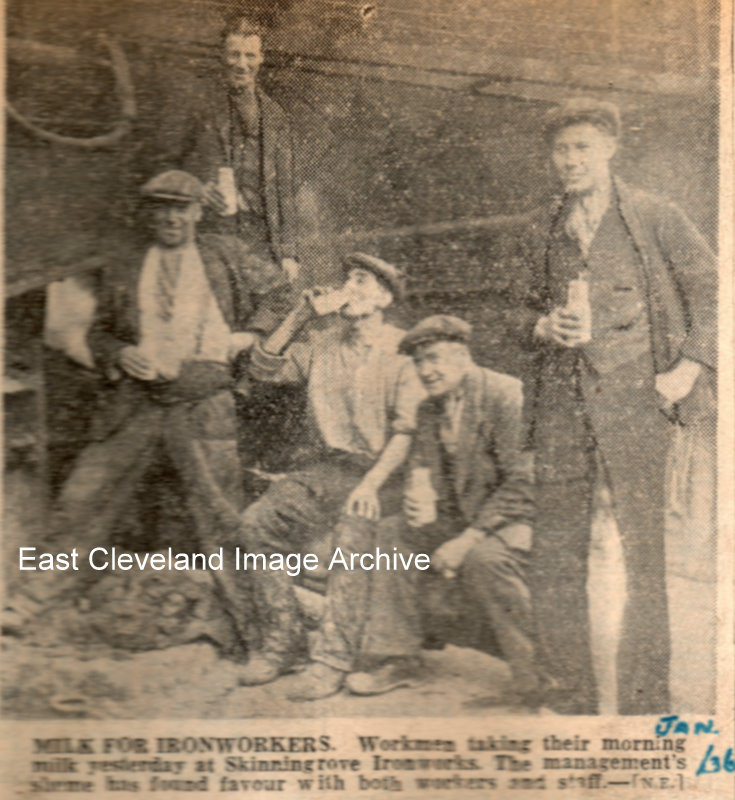

Yes 1936 and the workmen were given milk; which appears to be gladly accepted by the men.

Image are from our cuttings file (in the main from the Evening Gazette).

|

|

||

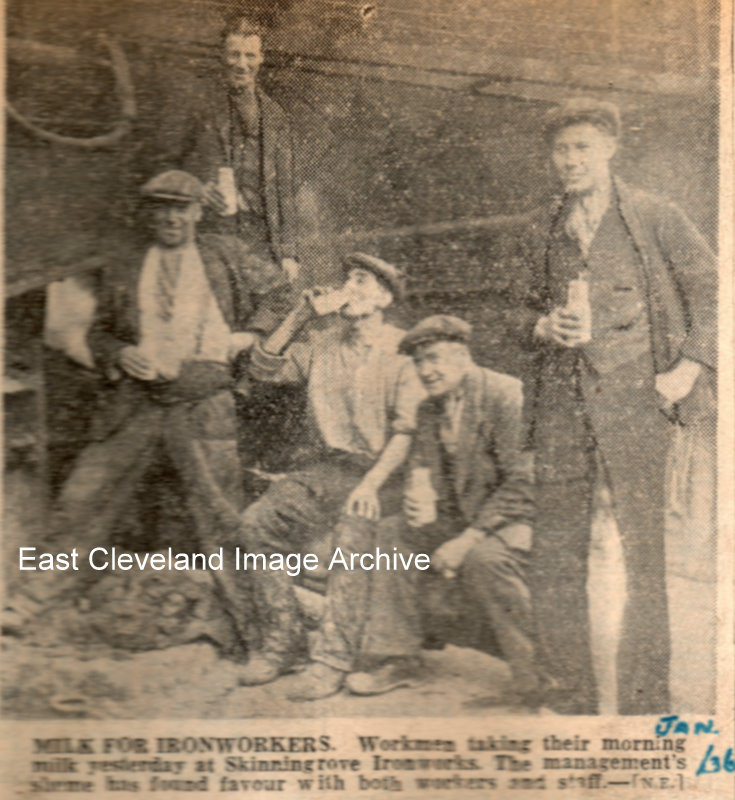

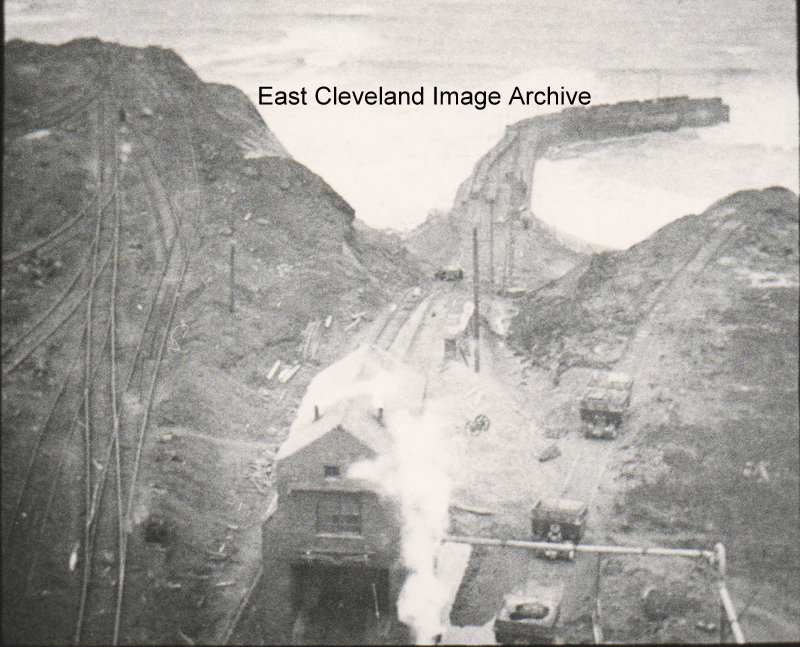

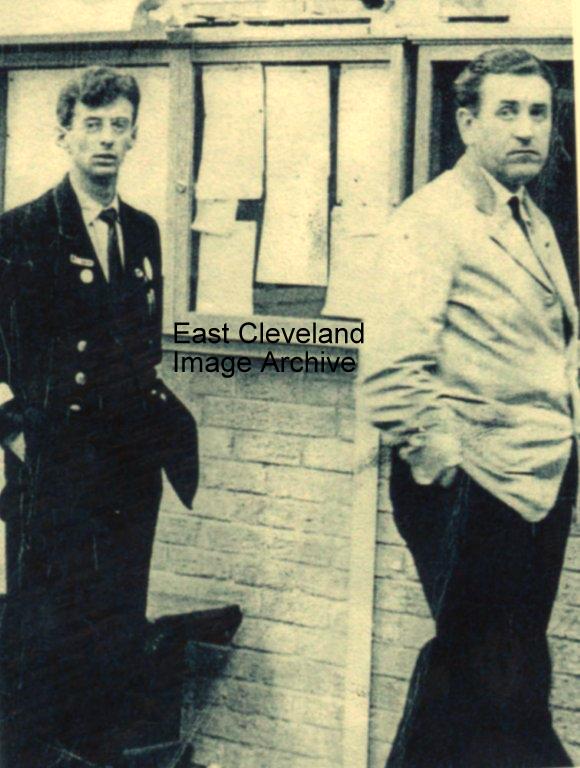

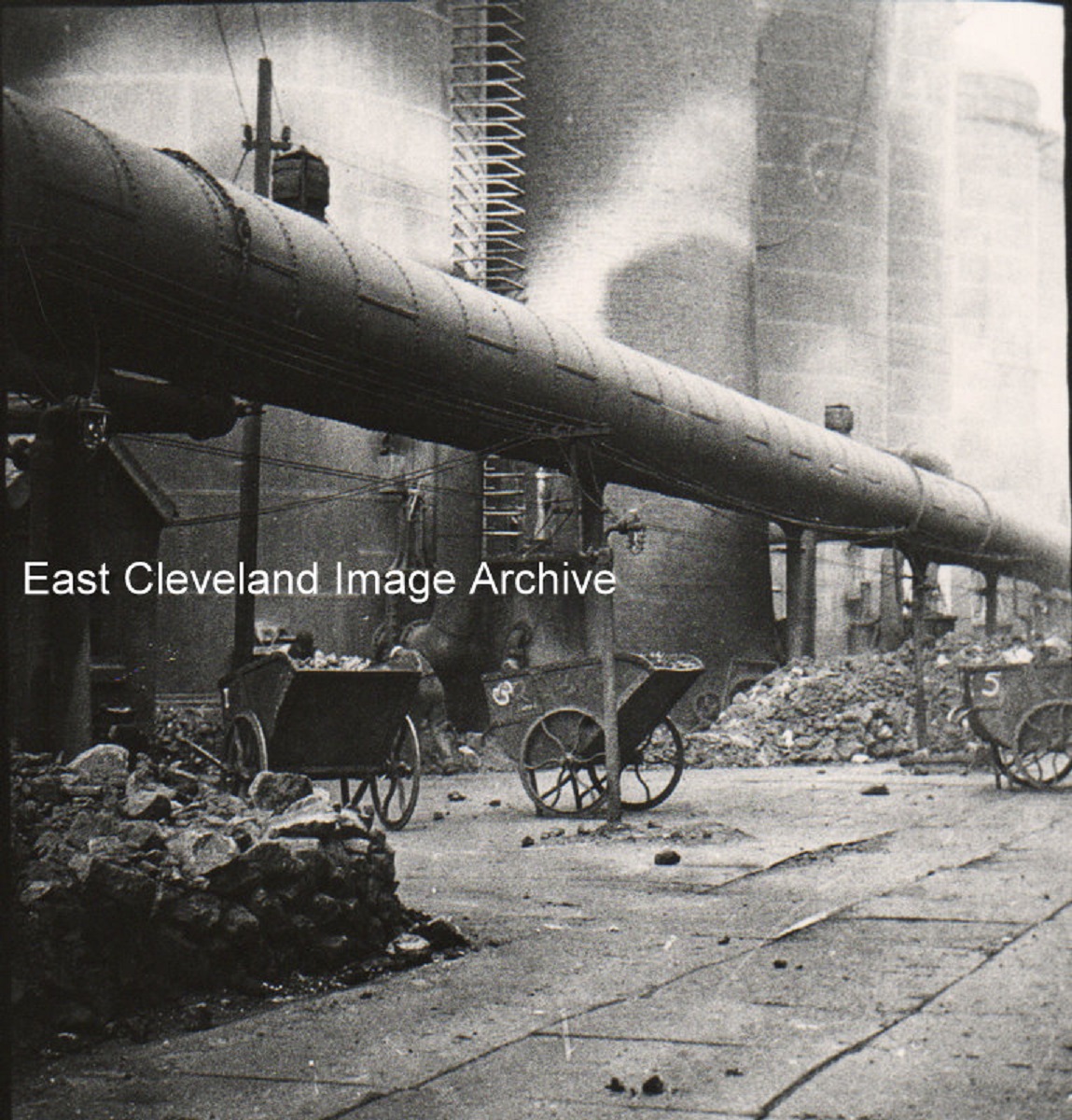

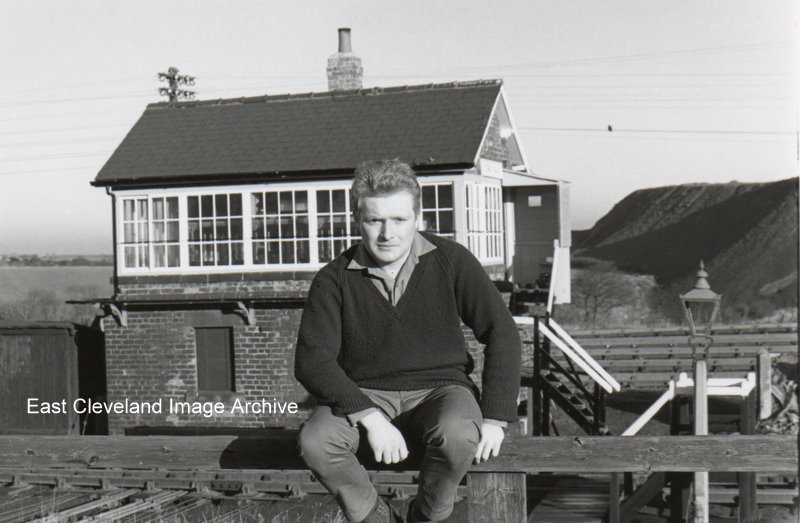

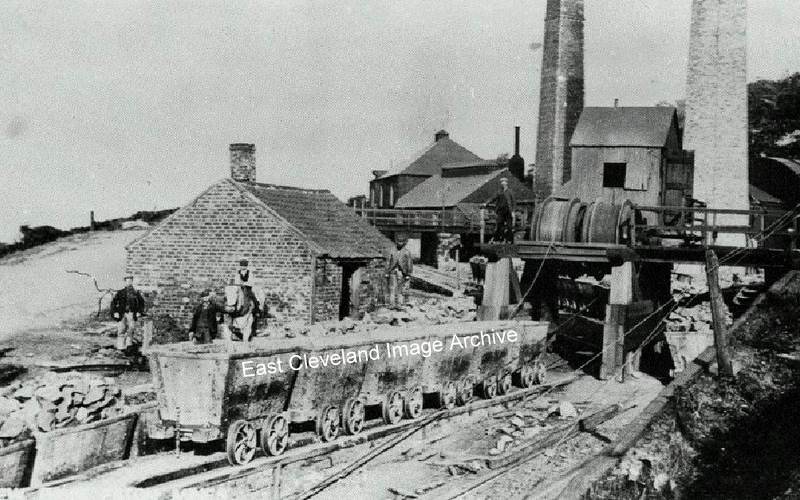

Yes 1936 and the workmen were given milk; which appears to be gladly accepted by the men. Image are from our cuttings file (in the main from the Evening Gazette).  Barring out calcined ironstone from kiln after roasting, taken to weighbridge and then placed on lift platform prior to raising to the charging platform at top of the furnace. Note the almost nappy effect on the workman’s trousers; this is in fact a protective pad (made from discarded belting) to protect from the heat which came from the calcined ironstone in the barrow. An early version of PPE! Image (from a glass plate) and information courtesy of Eric Johnson.  Well I couldn’t go wrong with this photograph could I? The name of the mine and the owners in plain sight on the building. The mine was situated close to Boosbeck and closed in 1954. Image courtesy of Eric Johnson.  Steam driven hauler on jetty bank about 1914, looking down towards the jetty. Image courtesy of Eric Johnson.  Yes bus drivers left Alan Chilton and right Frank Birtwhistle at the United garage East Loftus about 1962. The garage was later taken over by Arriva and is now closed.  A long time ago on Skinningrove works the ’barrows’ are there some still laden, they must have been very heavy for one man to pull when fully loaded, each barow is numbered and I am supposing each man had his own barrow. This further image of Mine Barrows in use at Skinningrove works also dates from about 1914, showing barrows already filled with ironstone awaiting hoisting to the furnace tops. Robert Silkstone pointed out the importance of these images: “these tubs are rarely photographed at ground level. They are the tubs that were taken by men who hand charged the blast furnaces before the conveyor system was introduced. The shape of the tub is deleberate to allow charging at the top of the furnace.” Eric Johnson explained their use at Skinningrove works: “At Skinningrove ironworks the term ”mine” refers to the ironstone carried in the barrows which came from the company’s Loftus mine, this stone was roasted in kilns and the calcined ironstone was taken from the kilns to the weigh machine cabin. Then weighed and the barrows hoisted to the furnace top, emptied and returned. Coke and limestone were also carried in the barrows, but they were always known as ”mine barrows”. Steven Partlett was able to confirm this analysis with: “My father worked these after Loftus mine closed and he moved to the Ironworks. What is not obvious in these images is that the ground where they operated was completely covered in plates which were either Steel or Iron. The barrows had a knife edged wheel, similar to a flanged rail wheel. The combination reduced friction, and made it easier to push the loaded barrows. The area was known in the works as “the plates” because of the feature.” These plated areas can be seen if careful attention is paid to the lower areas of these images. Image (from a glass plate negative) and information courtesy of Eric Johnson, also thanks to Robert Silkstone and Steve Partlett for the updated information.  Peter Miller sitting in front of the Crag Hall signal box. Image courtesy of Ted Morgan, via Eric Johnson.  1880 is the date on the photo, not the kind of men I would like to meet on a dark night; but the hours were long and the pay was small. Image (from a cutting) courtesy of Eric Johnson.  Eston Mine; with the Hauler which hauled the wagons (trucks) up, or let them down, part of the incline. The rope attached from the Hauler drums and the Hauler man on the left side on the Drum bridge. The square opening on the building behind was where the Hauler or Winder man looked out over the proceedings. Note there are also more trucks under the bridge going further up to the left and next section. Image courtesy of a compilation by Derick Pearson; also the supporting information.  Lumpsey ironstone mine, dating from 1895 (date as given on the image); one of the three mines associated with Brotton and immediate area. It was established in c.1882 and run by Bell Brothers Ltd. With shafts about 180 metres deep and in 1890 it was noted that drilling machines, worked by hydraulic power were being used in the mine. The mine employed 140 men and boys and produced around 3,000 tons of ironstone per week; by 1921 Lumpsey employed 480 people (340 working below ground, and 130 on the surface). In 1923 ownership of the mine passed to Dorman Long Ltd; the mine closed in 1954, bringing to an end the long history of ironstone mining in Brotton. |

||

Recent Comments