|

|

An obvious presentation, possibly First Aid as suggested by George Brown; but to whom, when and why?

Back row: Mr Cuthbert, Norman Myers,??, Dave Partlet.

Front row: Jim Easton, Albert Atkinson, Bart Groves, Brian Fergus on, Inga Cook.

We have added some names, but can anybody help?

Image courtesy of Dave McGill, names to date supplied by Eric Johnson, George Brown and Colin Hart.

Underground at Lingdale; viewed from the tub end, of a ”Cranner”, about to tip the stone into the tub.

Image courtesy George Pearson.

An excellent view; dating from November 1958 of a loaderman and his Eimco Mechanical Machine called a “Cranner” in Cleveland. The bucket picks up the stone and tips it into the tub behind the Cranner.

Image courtesy of George Pearson.

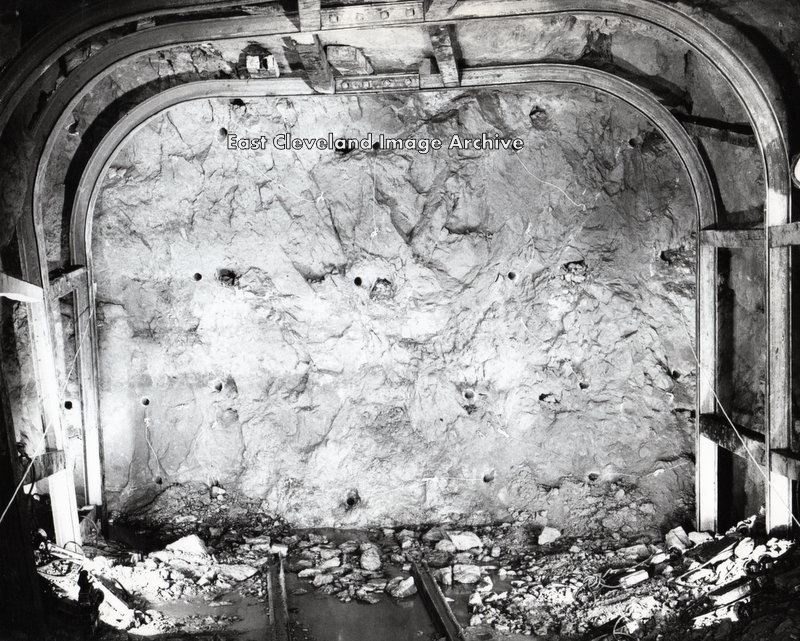

Showing the working face in Lingdale mine; holes for the explosives have been drilled ready for shotfiring. The roof of the place is being supported by steel mine arches, joined together by fishplates. Both arches and fishplates would have been rolled in the 18 inch mill at Skinningrove Works.

Image courtesy George Pearson.

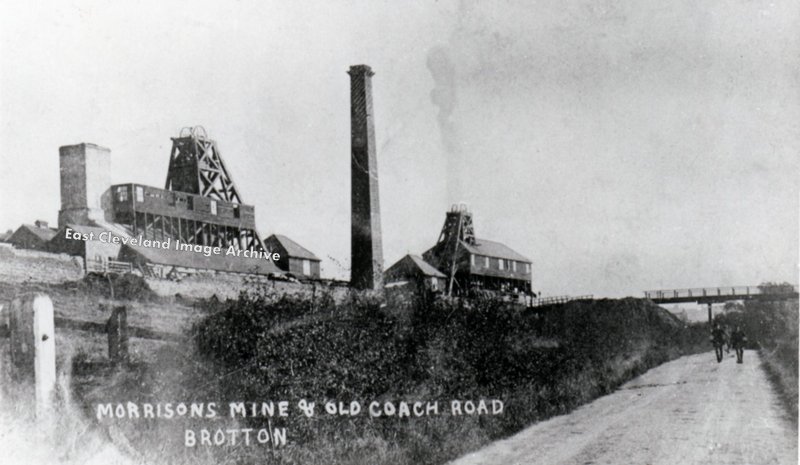

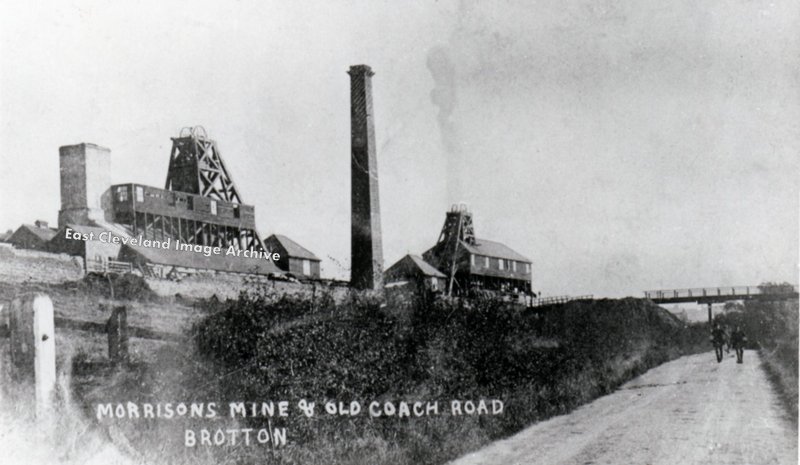

A view of Morrison’s Mine and Coach Road, Brotton. Morrison’s was an independently owned mine; output was at the requirements of the Ironmasters – so could be a little or a lot depending upon demand – so called as it was developed by Robert Morrison (he lived in The Grange, Brotton), imagine having this in your back yard? There was also a brickworks! The shafts were named after Robert Morrison’s wife (Florence) and his daughter (Mary). The overhead gantry was situated about where the children’s play area is on Coach Road today, but there are effectively no remains to indicate this industrial past. Liam White comments: “My ancestor, John Smithson worked at Morrison’s Mine. Not much more is known about him but I’m about to do some research.”

Image courtesy George Pearson, thanks to Liam White for the update.

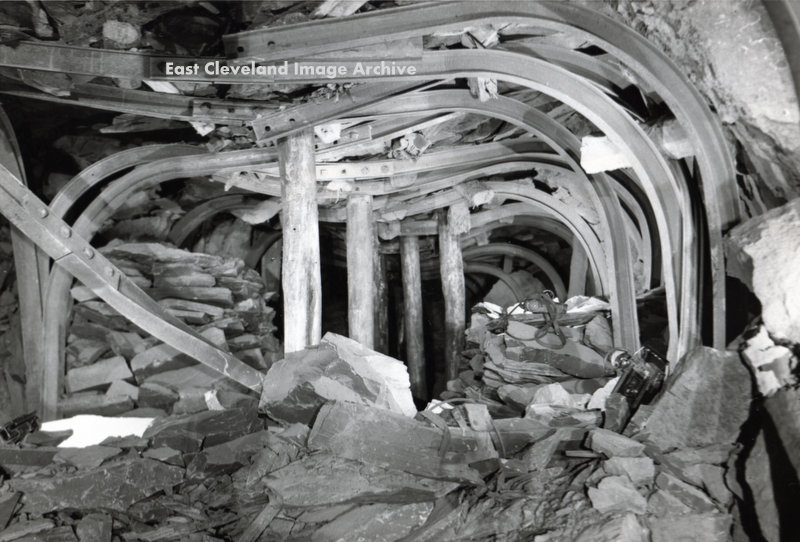

The effects of a roof fall in Lingdale Mine; the bent and twisted steel mine arches, are evident. The use of wooden pit props seem to be used to stabilise the roof.

Image courtesy George Pearson.

This view of a double track railway incline, is believed to be one of several located in Weardale, so although outside our area has strong connections owi ng to the iron and steel industry, hence the inclusion on our site. The quarries were used for the limestone for the iron and steel industry.A similar arrangement was in operation at Ingelby incline, which was part of the Rosedale Railway. Chris Twigg tells us: ”The location certainly looks like it could be Parson Byers, which was owned by Bell Brothers and Dorman Long so a good chance of a picture ending up in our area”. David Richardson also advises: ”Yes it is the incline head of Parson Byers Quarries, the track disappearing behind the trees to the right of the photo heads around to the main quarry. Very little changed at the incline between the 1890′s and 1920′s but the photograph was likely taken in that 30 year period.”

Any further information will be welcome.

Image courtesy of Maurice Grayson; also thanks to Chris Twigg and David Richardson for those updates.

A view of Kilton Mine; it seems strange to compare this busy scene with the present day site, which with one of the few surving ironstone shale tip in the district and a couple of derelict buildings, appears almost ghostlike today.

Image courtesy of George Pearson.

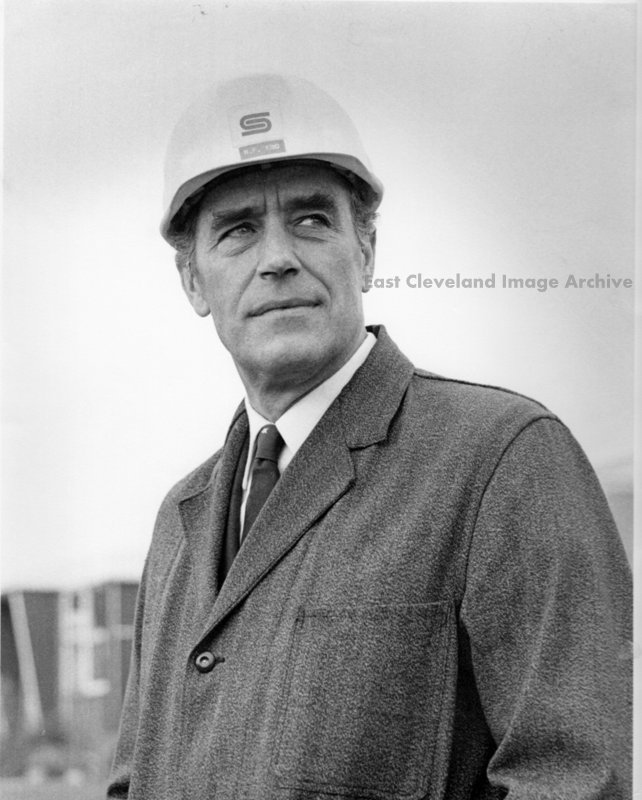

A photograph loaned to us by Dave Mc Gill, we asked: “Who is he and what was his job at Skinningrove Iron and Steel works?” Brian Young told us: ”I believe this is ? King works manager at the time.” Bob Doe assisted by telling us: ”He was the works manager and his first name was Bob”

Image courtesy of Dave McGill, thanks to Brian Young and Bob Doe for the updates.

A lovely photograph of Mrs Yarker from Carlin How, long time member of the St. John’s Ambulance. Further to Derick Pearson’s comment; researches have shown that Mrs Dorothy M. Yarker was born Dorothy Mary Duffy in 1917, marry Charles Henry Yarker in 1937; she qualified as a Nurse in 1946, and the 1939 Census lists her and her husband Charles (who during WW II was a crane driver at Skinningrove works) living at 68 Gladstone Street, Carlin How. Sadly Mrs Yarker left us in 1972.

Image courtesy of Dave McGill, updating information courtesy of Ancestry UK and other sources.

|

|

Recent Comments