|

|

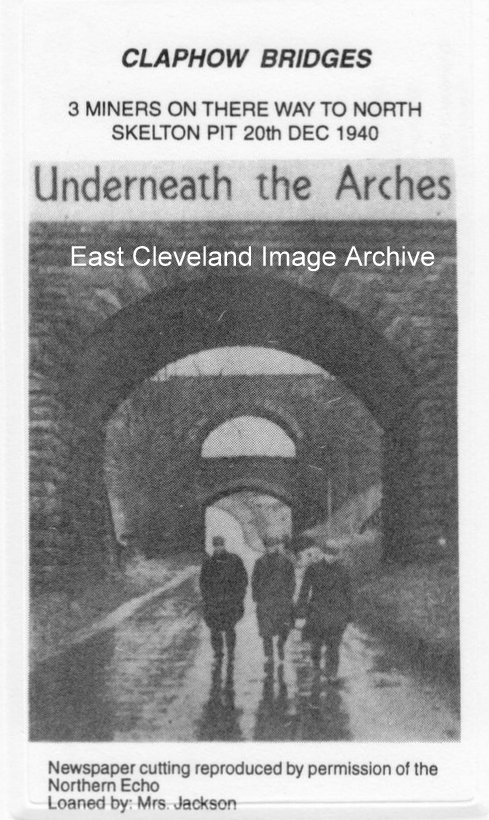

It must have been a wet walk that day, judging by the dress of the miners and the shining road. We asked ”More importantly can anybody identify the men?” and Paula Miller now tells us ”This is the Moody brothers of Lingdale”.

Image courtesy of Jeff Templeman and many thanks to Paula Miller for that update.

A good image of the engine house at Lingdale mine. The round brick kiln on the right was part of an attempt to make the mine profitable, using shale from the tip (especially during slack times). It wasn’t particularly successful, but probably contributed enough to prevent total closure of the mine. Lingdale mine was one of the deepest mines in the Cleveland system and also had the poorest yield, there being a large band of shale splitting the seam in two. This resulted in the huge shale heap which took forever to dispose of! Lingdale village was described as almost derelict in the late Victorian era, the difficulty of winning the stone meaning that the mine was closed more often than in production.

Image courtesy of Maurice Grayson.

Albert Dobson of Carney Street, Boosbeck; Gus Coote and Clarence ‘Clarry’ Ditchburn of Moorsholm leading out the mine horses on August 28th 1959. Because of the height of the ironstone seams, horses as opposed to ponies were employed in the Cleveland District . These details confirmed by Ann Jackson: “Clary or Clarence Ditchburn was my Dads cousin and lived at Moorsholm. His Mother was Elizabeth Ditchurn nee Shaw.” and Janice Walker: “Clarence was my uncle ,he was married to Mary.My dad was Reginald Ditchburn he left Moorsholm to live with his sister Eva May Stanforth in Leeds.”

Image courtesy of Maurice Grayson, with updated information courtesy of Alison Small and Lingdale History (Communigate). Thanks also to Ann Jackson and Janice Walker for the updates.

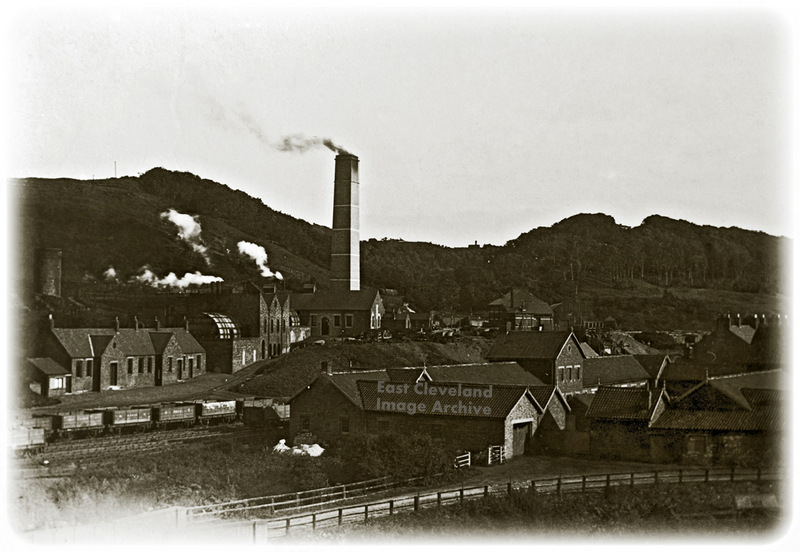

An early image of the mine; Deepdale valley has not been filled in with shale at the date of this photograph. The semi circular mine fan housing of possibly the Cooke ventilating fan, can be seen. The building and fan were replaced by a 30 foot diameter Waddel fan.

David Richardson tells us: ”Taken sometime in the 1890′s, both the 1872 and 1874 Cook’s Fan houses are visible with the Compressor House and Boiler Plant Chimney behind them. A little away from those to the right is the Hauler House for the South Drift. On the hillside to the left of the photo is a large chimney which was the original furnace shaft for ventilating the North drift but was likely only used for a few years before the 1872 Cook’s fan took over.”

Image courtesy of Michael Garbutt and many thanks to David Richardson for the update.

This image of Loftus Foundry is part of a series taken by Eric Johnson around the area; featuring Loftus views. We will be displaying more as time passes, showing the changes in the area.

Image courtesy of Eric Johnson.

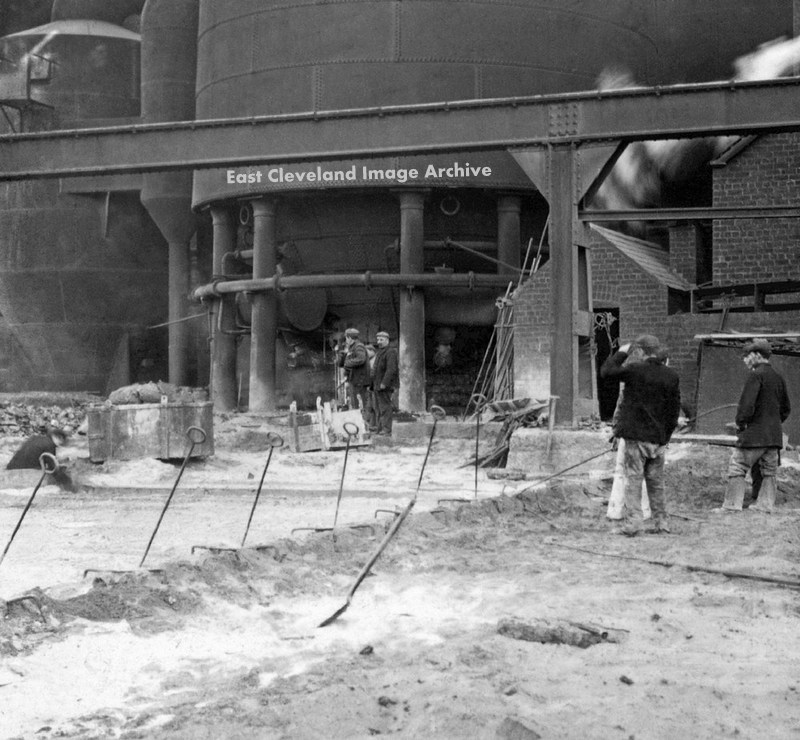

On the sand bed in front of the furnaces, a slinger guides a lift of pig iron. It was normal to use a flap of leather looped over the wrist to protect the hand from the still hot pig iron. The sand bed is cool enough to not need the wooden clogs normally worn; behind the slinger the impressions of the sow and pig channels can be seen in the sand bed.

Image (from a Glass Plate Negative) courtesy of Dave Mcgill.

When the furnace has finished casting, the pigs are attached to the sow and the crew have to go around and break them off and heap them together, using the tongs they are holding and stack them into bundles ready for slinging. A hard physical task.

Image (from a glass plate negative) courtesy Dave McGill.

On the sand bed; with the gate irons in place ready to divert the flow of metal to fill the pig moulds. The furnace is preparing to cast. As one sow channel is filled, the gate is placed to divert the flow of molten iron to the next sow channel.

Image (from a Glass Plate Negative) courtesy of Dave Mcgill.

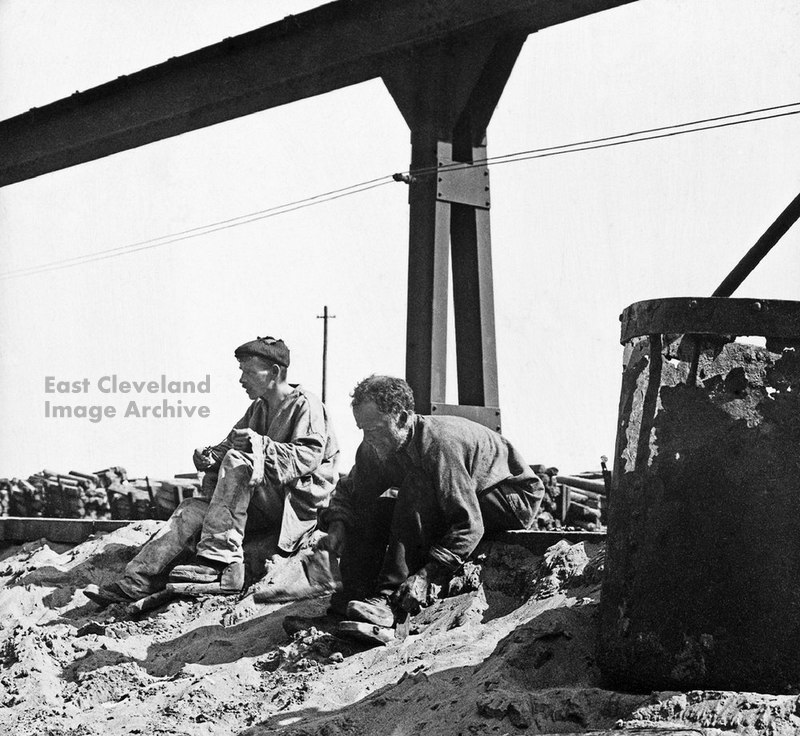

This image shows both men strapping on clogs – shaped wooden soles to protect his boots from the heat – before going on to the sand bed to break up the still hot pig iron; and stack it ready for the crane to remove it.

Image (from a Glass Plate Negative) courtesy of Dave Mcgill.

These two men are preparing the sand runners (sows) and moulds (pigs) to receive the molten Iron from the blast furnace. The man on the left is raking the sand smooth, to the right the man is using a tool known as the ‘Worker’ making the mould for the pig. Ed Jones commented: “This pig-bed sequence may well be the Normanby Ironworks as there is a large travelling crane gantry seen on all the photos and the OS 6″ map (surveyed 1913) shows a travelling crane at those works.” However knowing the source of all these images as being Skinningrove works, the Archive believes these are the blast furnaces at Skinningrove.

Glass Plate Negative courtesy Dave Mcgill, thanks to Ed Jones for the suggestion.

|

|

Recent Comments